I’m not going to quote the Joe Walsh song, we all know it and it’s horribly cliché. But it’s the only song I know about a Maserati (if you happen to know of another one, leave a comment!).

No, I didn’t make it up to 185, have to keep things real, as well as within local speed limits.

Sylvia performed marvelously, aside from a temperamental starter – I thought that was fixed?!? I noticed at the start of my drive that there were a lot of rattles, creaks and noises in general. After a while everything seemed to settle down, and even later things were perfect, the only noise coming from the shifter badge that rattles once in a while. I notice that the asphalt quality has a lot to say as far as noise levels in the cabin go, and taking a few really nice long drives helped shake things down and allowed everything to settle in.

The first drive was in a downpour, and I was happy to note that not a single drop of water entered the cabin anywhere. Dry as a bone. The new seals perform perfectly, and also help to keep noise out.

A long drive on the freeway was uneventful, the car performing admirably, cruising along smoothly and rapidly for hours on end. Because of the comfort of the interior, you don’t really notice the acceleration or the true speed you’re traveling. 80mph feels more like 50. Hit the gas and you can see the speedometer gain rapidly, but the acceleration feels effortless. It’s very refined.

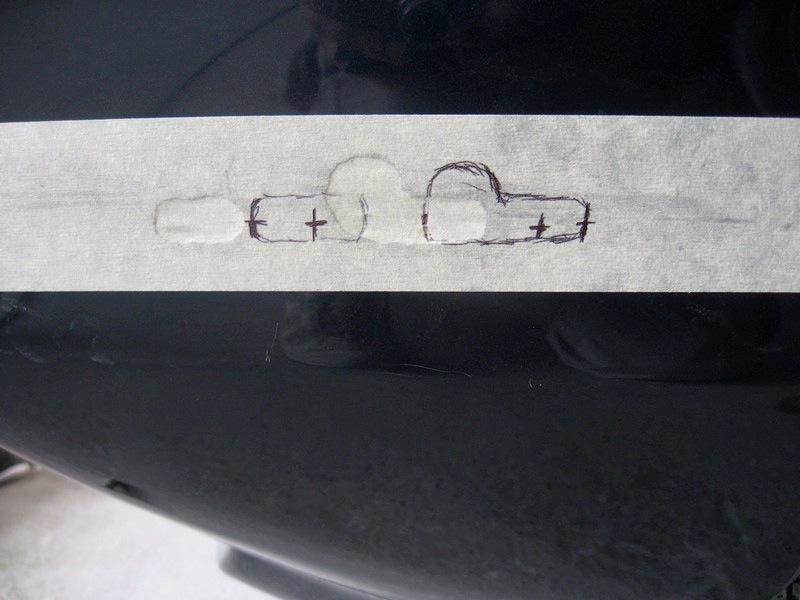

There’s still a bit of vibration between 2200 – 2800 rpm in 3rd gear. One guy I spoke with said he suspects it’s the prop shaft and commented it immediately when we went for a drive. He thinks it probably happens in 1st and 2nd as well, but isn’t as noticeable at lower speeds. It’s not a huge deal, and the prop shaft went back into the car in the exact same orientation as when we took it out to overhaul the transmission (we marked it), but it is something I’d like to have checked and make sure it’s correctly balanced.

The new front headlights are brilliant! Literally. They light up the road so much better and are extremely precise in their throw, you can see exactly what area they cover perfectly, and it’s exactly the area needed to drive at night. The high beams only increase the reach and are nicely constrained to the road and shoulder. Kudos again to Daniel Stern, this is one of the best improvements I’ve made to the car.

Hit a double rainbow on the last drive, don’t know if you can see it. It’s lovely how the water beads on the car and simply rolls off.

I’m very pleased with the color, it suits the car so much better than the purplish blue it was painted in before, and the depth and richness of the Blu Sera is truly striking.

All in all I’m extremely satisfied, and really happy to have the car back on the road.

Please don’t be tempted to think that this is the end of this blog – this is after all a 33 year old car! Next up is to put her on the dyno and see how many horses have escaped over the years, and if we can get them all back in the corral…

Comments are open!