Been a while since I’ve posted anything, but a lot has happened. Will do my best to fill in patient readers and followers of this humble blog.

I decided we needed to do the bumpers right, which meant re-doing some work.

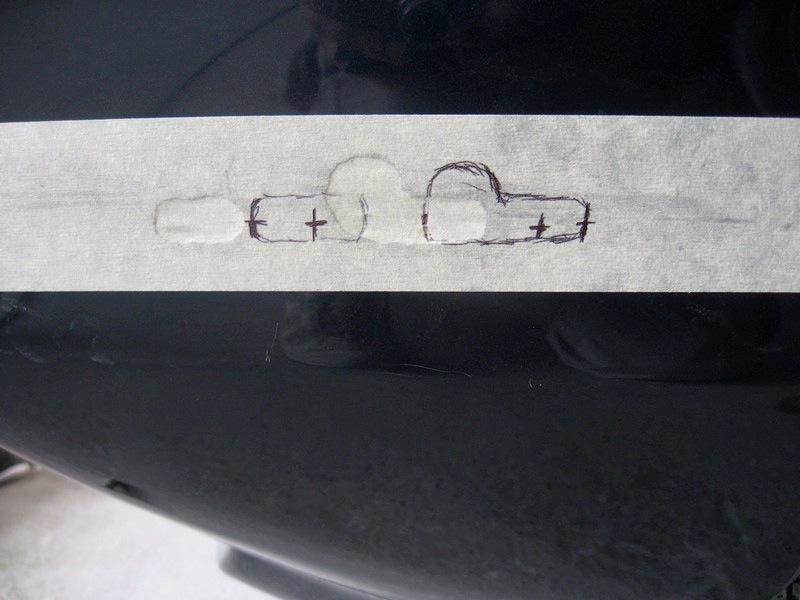

“front bumper mounts re-drilled/cut, new metal sections welded in to ‘fill’ the gaps and filled/shaped smooth ready for priming.”

“A little good news on the rear bumper corners – the holes in the body were the same measurements on Mr X’s car as yours which completely confused me for some time until I compared the rear bumper corners from your car with his, all of the rear bumper corners have provision for THREE mounting holes, even though only two are used and have threads fitted, this allows the bumper corners to be interchangeable and no need for different spaced holes from Euro to USA spec. Whilst the holes are there though, there is no thread for the bolt so we have spoken to the engineering company a few workshops down from us and they are going to fit thread inserts in both rear bumper corners to align with the existing holes in the rear of the body.”

The shop and I both agree that the EU version looks much better than the US. While the differences are much more subtle than say on a Ghibli, Bora or Merak, the bumper placement and H4 lights does change the entire balance and feel of the car as a whole. All in all I’m glad we took the extra time and effort to complete the transformation.

(p.s. for those of you wondering if “Mr. X” is the same as “Racer X”, we can’t be 100% sure, but the fact that he drives a QP3 and not something more exotic and sporty would indicate that he probably isn’t the mysterious driver known only as Racer X)