..and they were all mine. This blog isn’t called “Automobiles for idiots” for nothing!

An old woodworking saying says “measure thrice, check twice, cut once”. There are wisdom in those words.

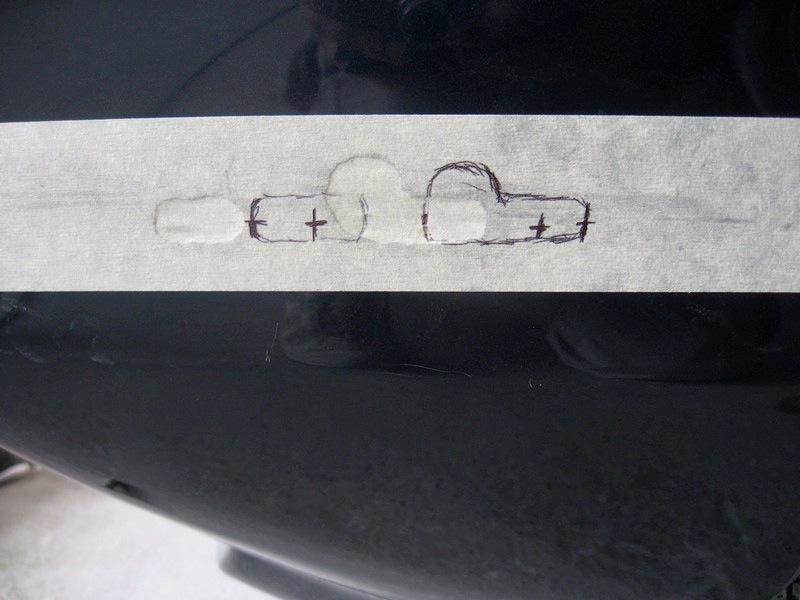

Much care was taken while doing the bodywork, tack welding in new sections temporarily to make sure everything fit correctly before committing the section to a permanent weld. Windows, doors, and other areas were all checked carefully. The front panel was also measured and checked carefully against a Euro model to ensure that the front lights and bezels would indeed fit with minimal modification. Looking at the bumper, it appeared that the two mounting posts projecting from the front and rear of the car ensured that the US spec cars’ bumpers stand further away from the body compared to the Euro spec version. Cutting them down to match the EU spec dimensions seemed the logical way to adjust the bumper for the Euro look, more integrated with the body.

What we didn’t realize until it was too late, was that the side bumperettes are also offset together with the main bumper by the same amount, approximately 25mm/1″. So cutting the mounting posts down to size brings the bumper 25mm closer to the car, but the side mounting brackets are 25mm further forward on the US version than the EU version, meaning that there isn’t room for the “accordion” covers that provide a unified look of a wrap-around bumper. The bumper and side bumpers simply won’t fit, they crash.

Oops.

There are 2 options from here:

1. Fix the mounting posts so that they are as they were, i.e. the longer US version. Everything will fit. The car will have EU lights and front, but US bumper fit (further away from the body).

2. Strip the brand new paint and bodywork at each corner, cut out and move the new mounting brackets 25mm towards the rear of the car, fill the resulting holes, do body shaping, priming, guide coat, final shaping and repaint all over again. (and of course do the same thing for the rear mounting brackets as well, moving them forwards from the rear of the car by 25mm).

Should I do the right thing, or the easy thing, or are they the same thing? Thoughts?