Having replaced the starter motor in the car with the one thoughtfully provided by the PO when I overhauled the transmission, I was surprised to be getting the “click – nothing” sound after only 6 or so months.

It can mean many things, but seeing as how I was getting power, all instruments checked out, and I could hear the starter relay clicking, the finger seemed to be pointing at the starter. Sometimes she would start right up on the very first try, other times it took a few repeat attemps, and lately I had on occasion been spending 10 or 15 minutes before suddenly it would catch and the engine would roar to life.

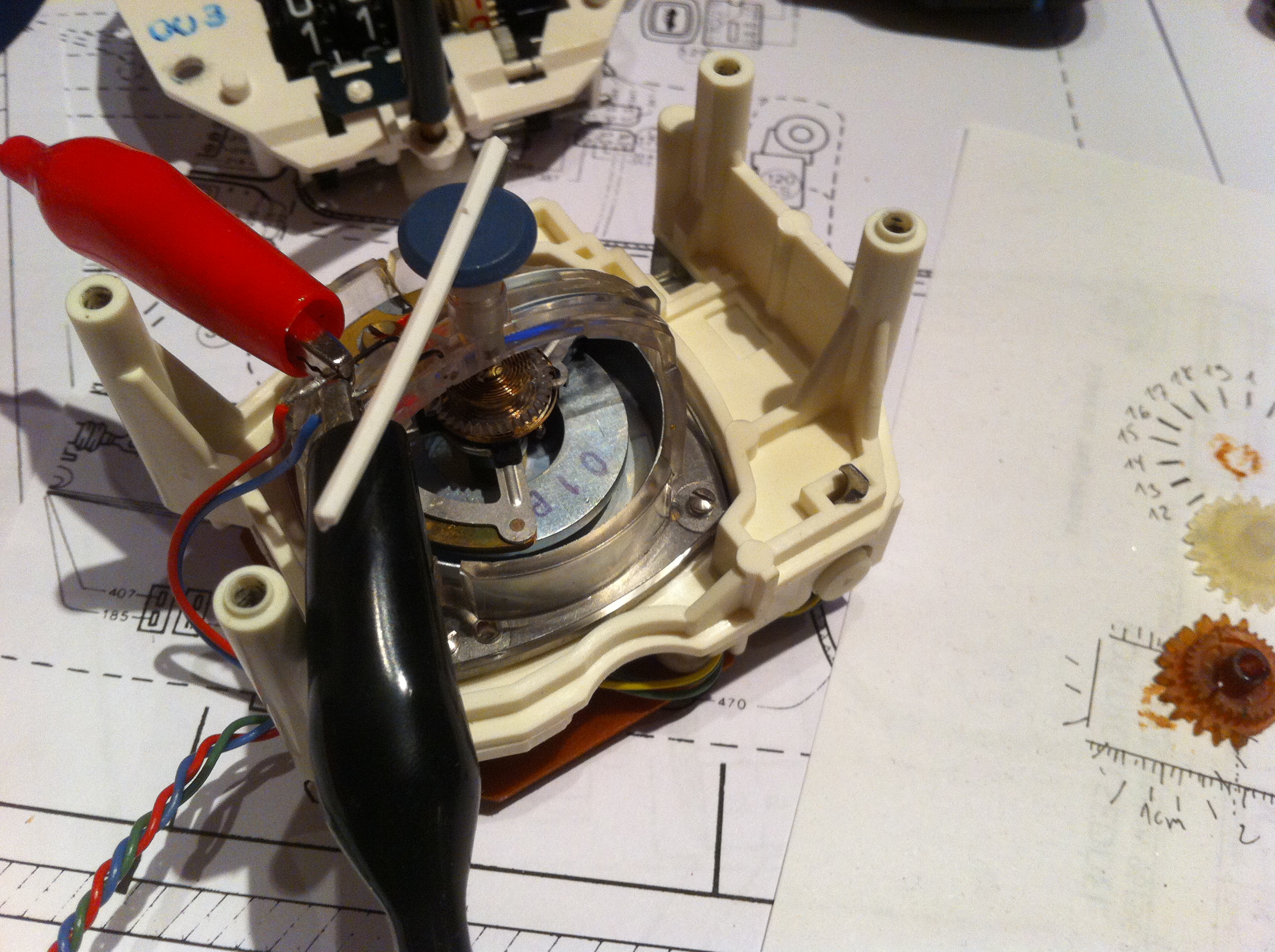

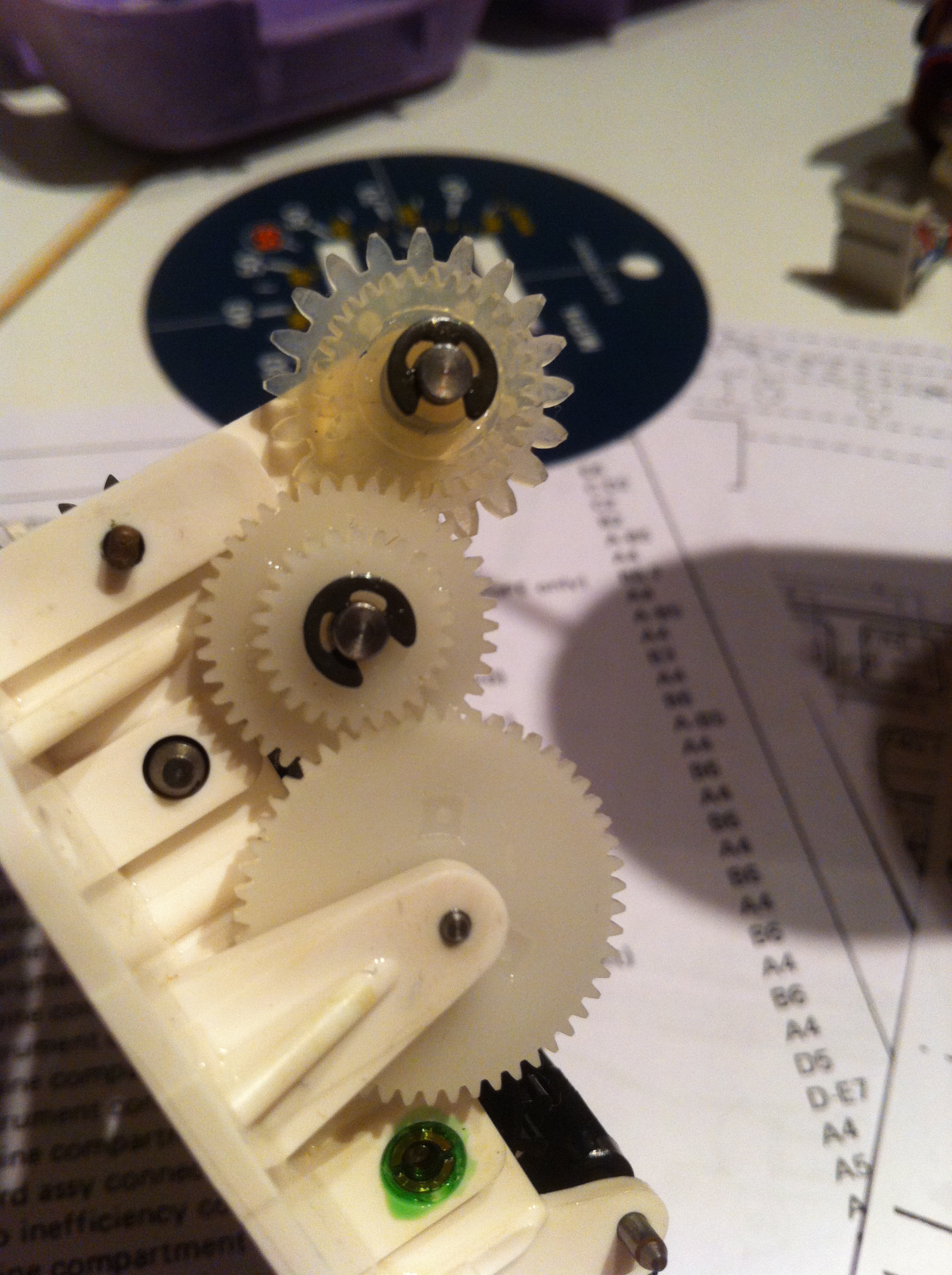

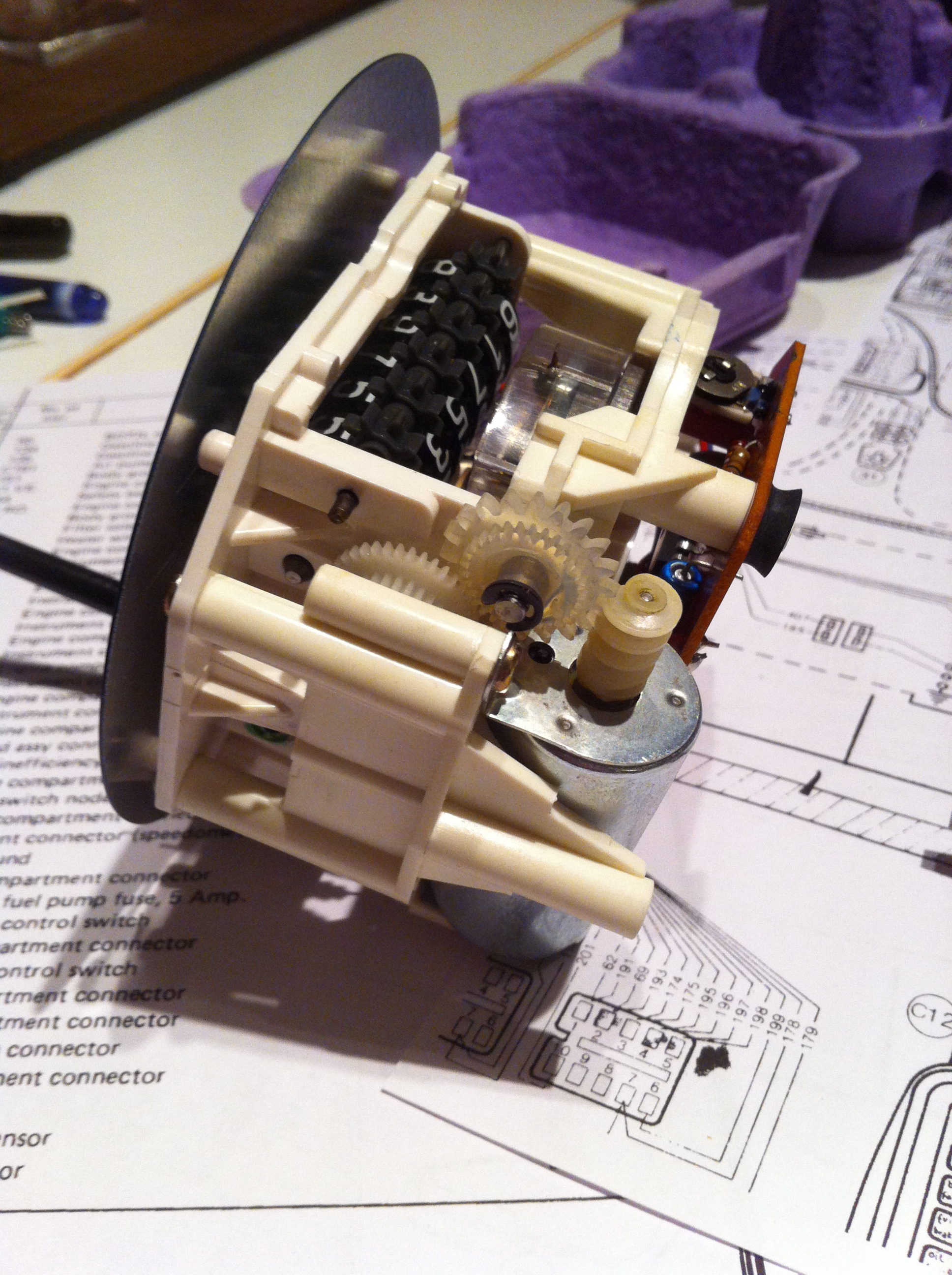

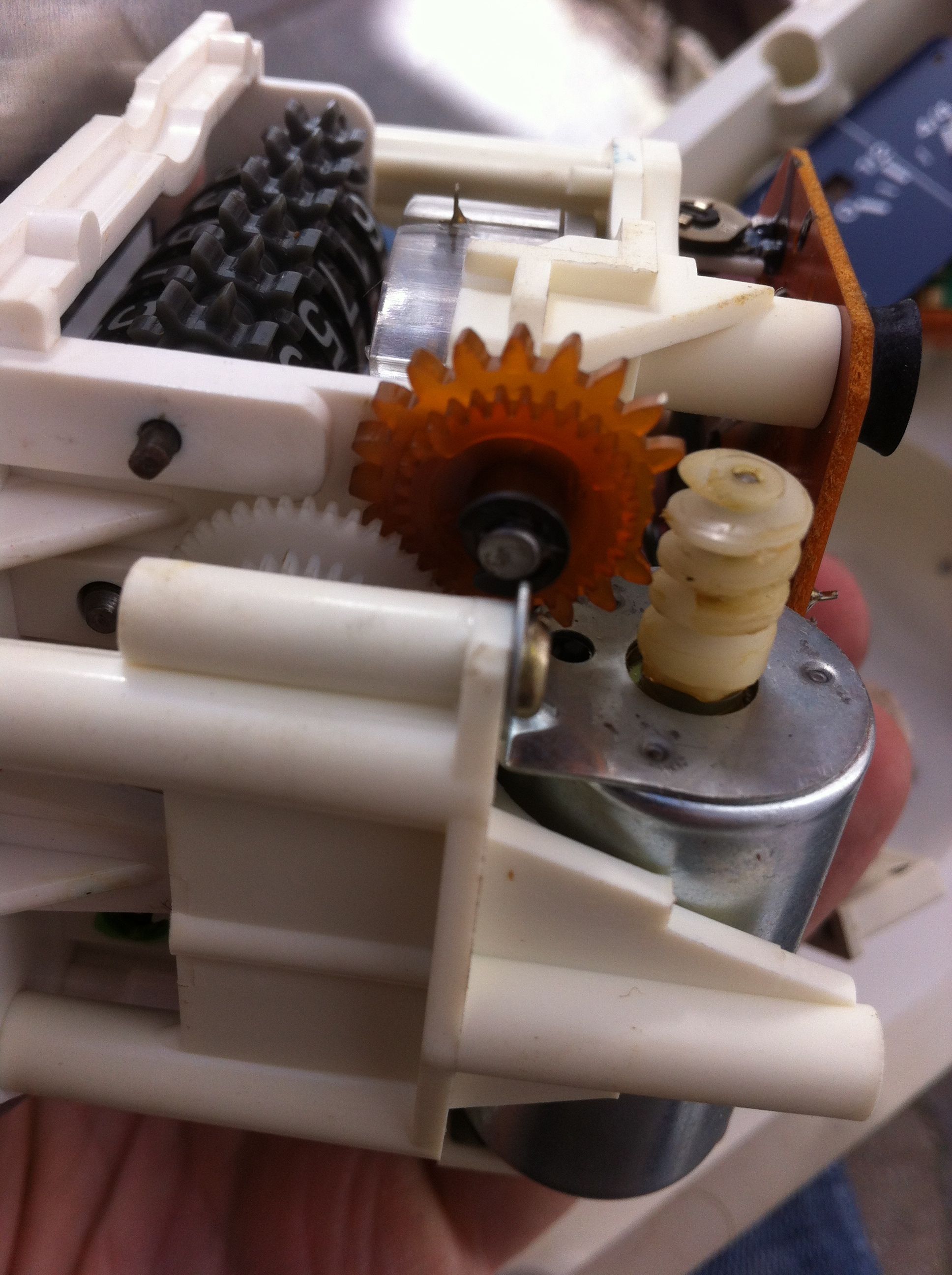

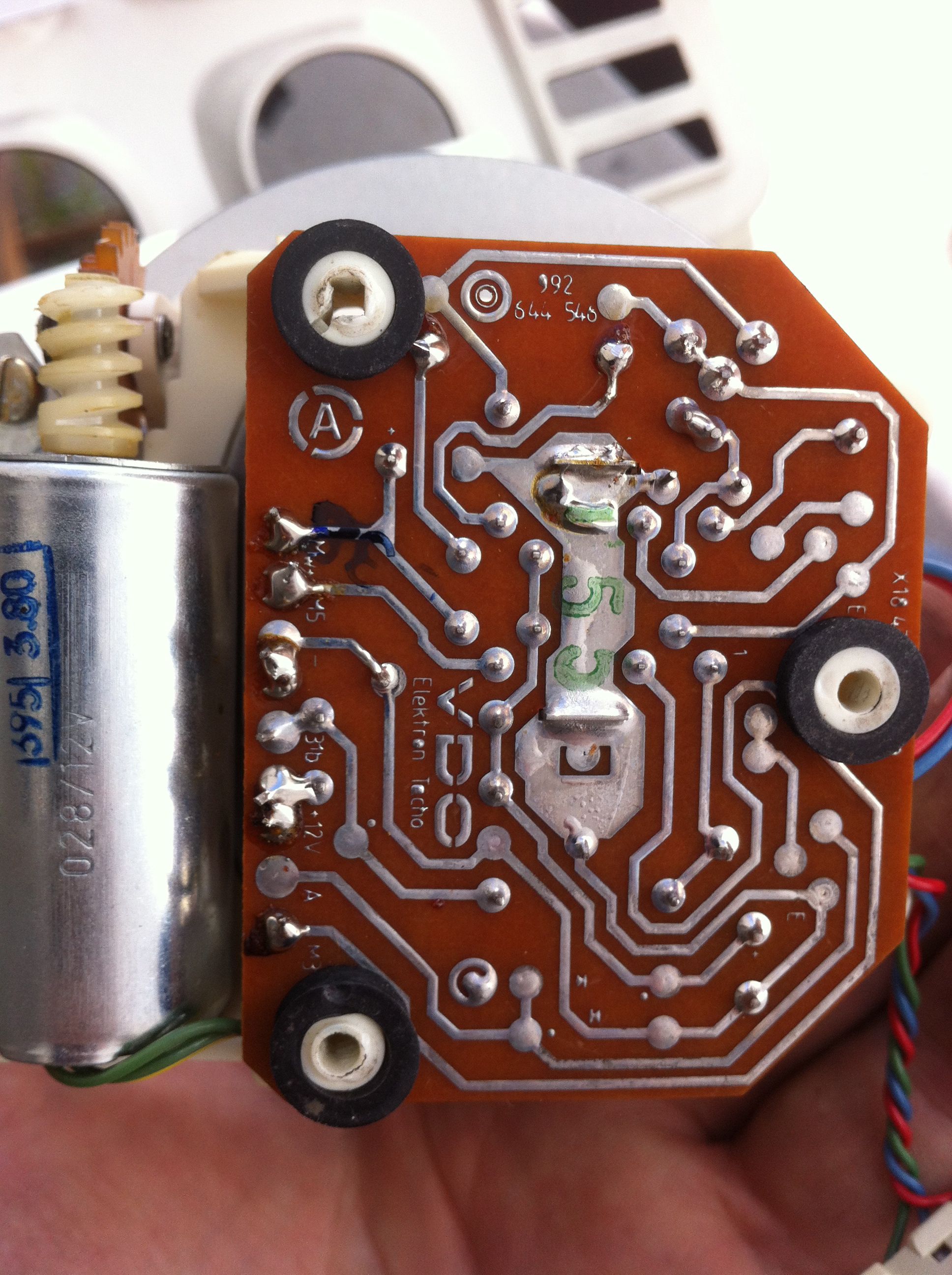

I delivered the starter motor I had pulled from the car to a local shop. Thankfully Maserati did the same thing here that they had done with the transmission – sourced it from Chrysler. Turns out they’ve used the same basic design from the 60’s up to about the 90’s. Of course Maserati also managed to mount it in such a way (upside down and backwards) that any condensation, rain or other moisture collects inside the starter, guaranteeing it won’t last for too long before needing to be replaced or repaired.

For reference, it’s a 1.8HP Chrysler starter, part number 4091950, also used in the 1980 Dodge 1/2 pickup truck.

The parts shop was unable to find the rebuild kit needed (not a lot of American cars here), so I obliged and ordered 2 rebuild kits and 2 solenoids in order to repair them both. Found them at “Alternator & Starter Parts Wholesale” www.ASPWholesale.com, part no: 66-302 (solenoid) and CH-79-1100 (brush holder, rings, washers, brushes, the whole kit). Total price $71.82 plus shipping for all parts for both starters. Not a bad deal.

Got the car into the shop that had the extra starter, brought along the parts, and this afternoon was able to drive out with a decidedly easier-to-start car. And an extra rebuilt starter. Always nice to have a spare in reserve.

Getting another thing done on the car is always a reason to celebrate, that combined with the cold but dry weather brought us to a local establishment offering a good old fashioned by-hand car wash. Well, they use hoses and sprayers and all sorts of special products, but most importantly they all loved the car :-).

She’s clean, she starts, she’s garaged. Not a bad start for autumn.