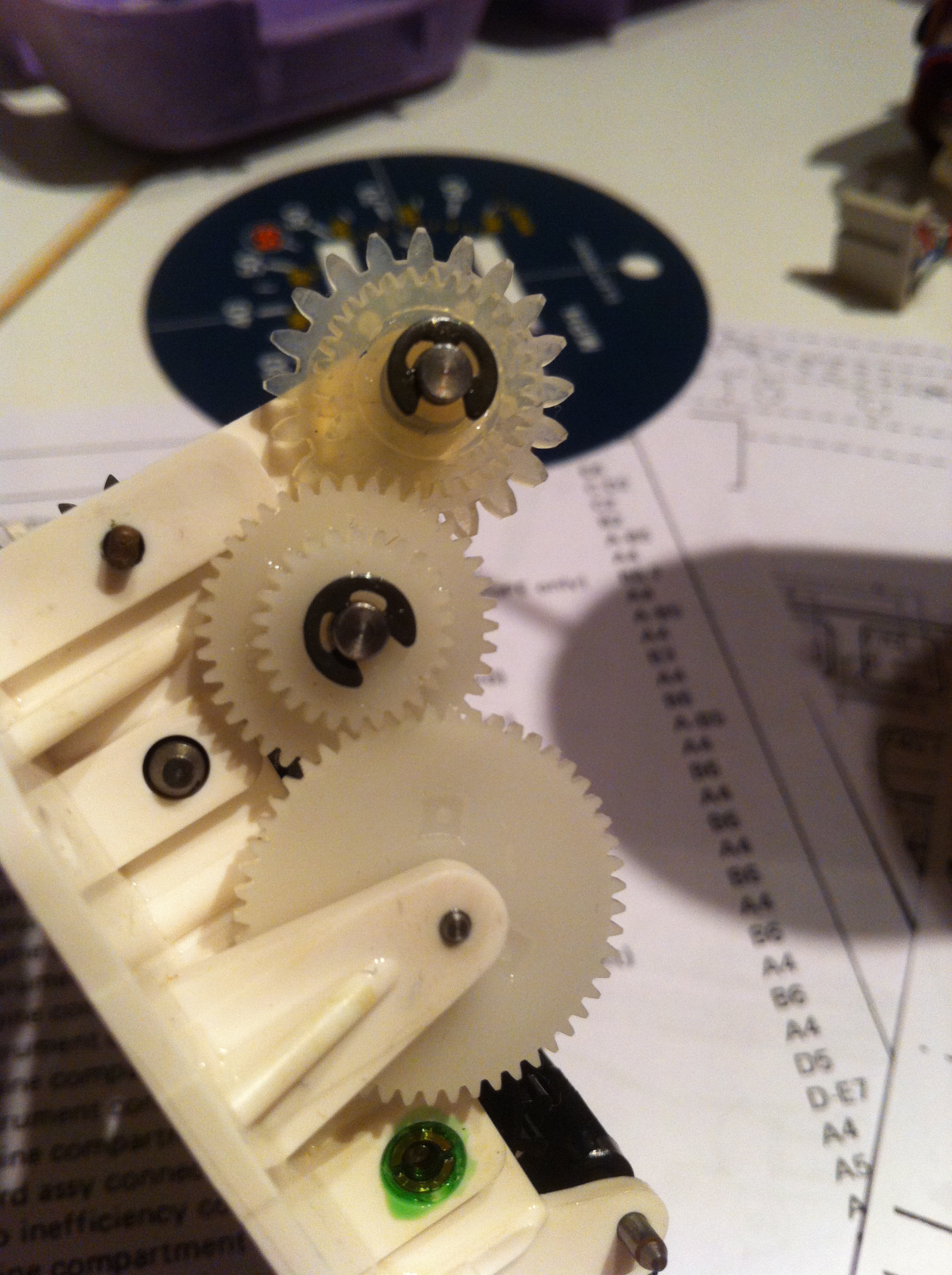

My new odometer gear arrived today, courtesy of Palo Alto Speedo in California. The old one had crumbled into tiny pieces, I have no idea when. The speedometer hadn’t been working since I received the car, and I’ve been trying to do what I can to fix it.

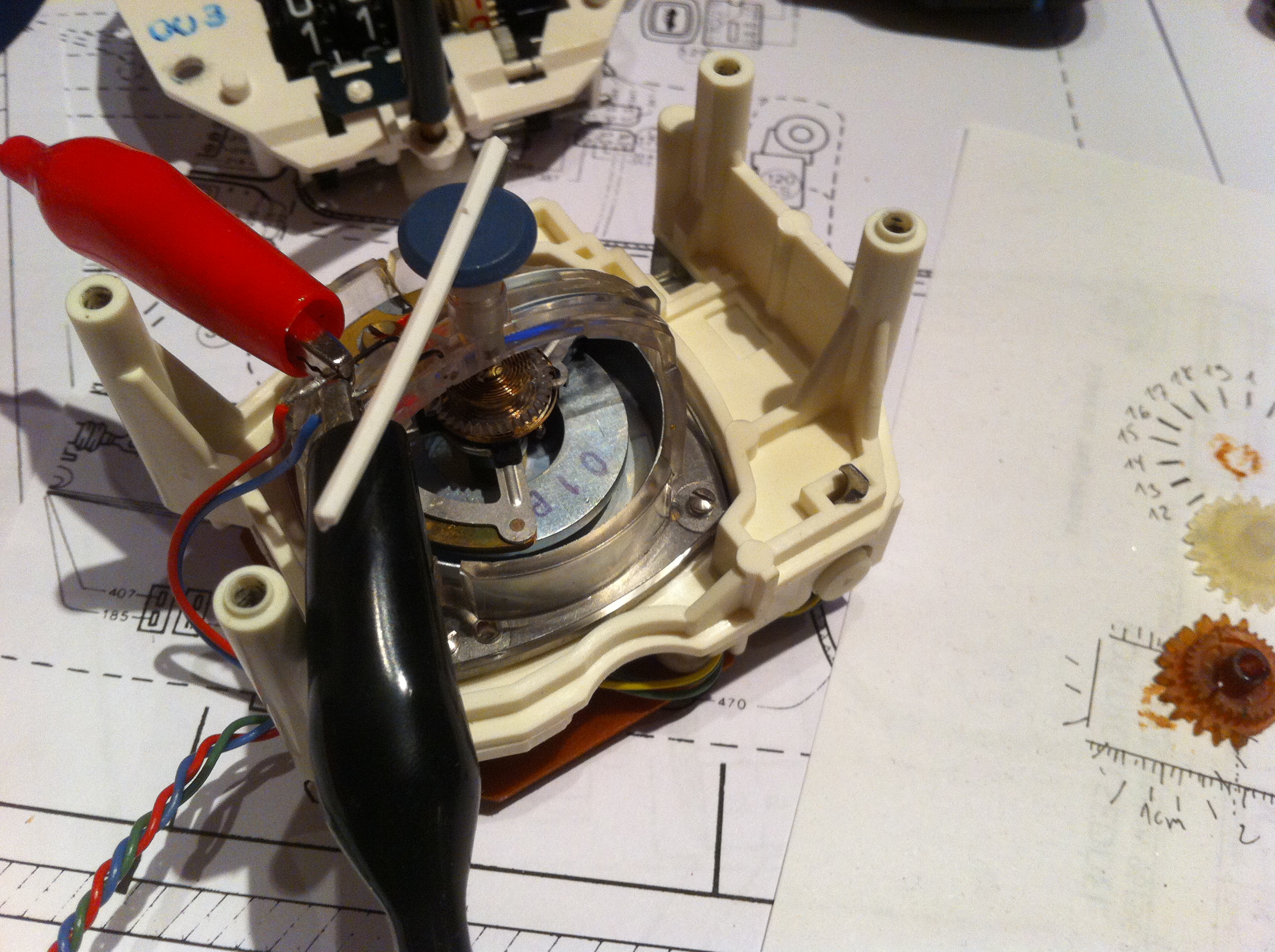

When I overhauled the transmission, I also dismantled and checked the speedometer pulse generator and reduction gear, it’s a small assembly that takes the mechanical rotation of the speedometer from the transmission’s output shaft and uses it to run a tiny generator, not unlike those found on bikes in days gone by. This sends an electrical signal to the instrument cluster and speedometer. I had hoped that by repairing it (there was a drive bar that was worn and too short) my speedometer would work again, but no such luck.

While speaking with several knowledgable people in the US about this, I learned that there are no standards whatsoever as far as speedometers and the impulse generators go. Some send out square waves, other sine, some are very low level, other high, and there are a variety of impulse per mile versions. Every car maker had their own system, especially when electronic instruments were just becoming common, i.e. in the early 80’s.

I did run it with a drill and measure the output, I neglected to note it but seem to recall it being approximately 0.5v DC.

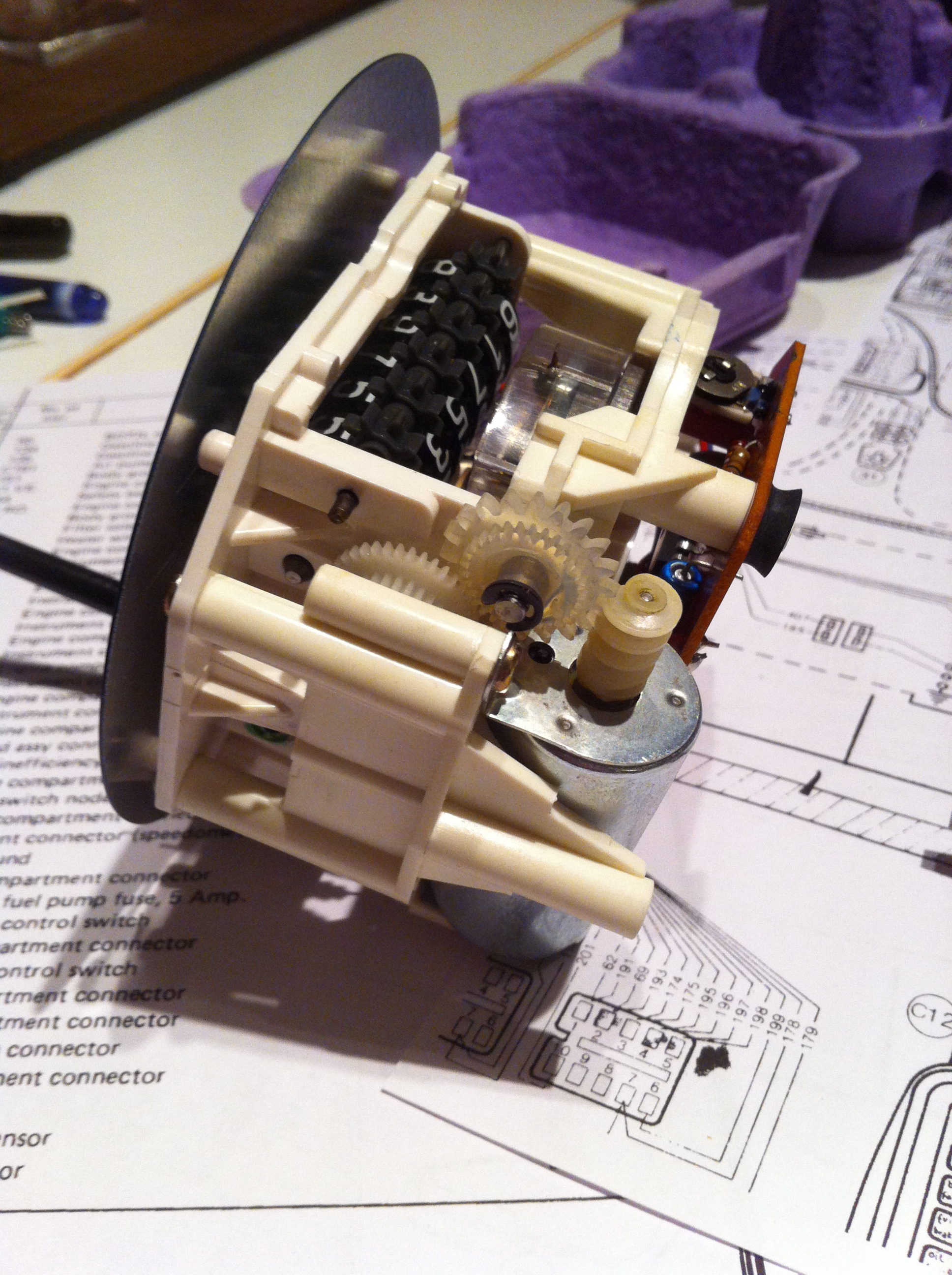

Installing the odometer gear was easy, regardless of the problems with the speedometer. The new gear is also soft, but much less than the disintegrated and discolored original. I’m told they’re made like that so that they don’t make any noise, I don’t know if that’s true. The instruments in the Quattroporte are made by VDO and are the same as those used in contemporary Porsches. The electronic input board is Jaeger, the aforementioned gear reduction and pulse generator unit is Arthur Allen (unfortunately they’ve recently closed down, and are no more).

VDO USA recommended that I talk with Nichols Speedometer in North Carolina for help troubleshooting the speedo. “Chuck”, a wonderfully experienced gentleman with a southern drawl on the phone had a few tips. I applied 12v DC to the two wires connecting to the actual speedo coil, and the needle jumped to the far end, indicating at least that part is working. Touching 12v DC to the same colored wires on the PCB didn’t result in anything, however.

- 6 screws (3 top, 3 bottom) secure the instrument binnacle to the instrument pod/cover. They might be filled with goo to keep people from opening it up.

- 8 screws attach the instrumentation holder to the front panel of the instrument cluster. 3 screws with serrated washers fasten a flexible strap carrying electrical power on to the upper front of the binnacle for instrument lighting.

- 4 screws hold the speedometer in the plastic casing. There is a small molex connector on the front that needs to be unplugged.

- 2 tiny screws hold the faceplate on the speedometer, each has an almost invisible clear plastic washer. 4 screws at each corner hold the two halves of the plastic enclosure together. There is a spacer/insulator between the speedometer innards and the front faceplate. The indicator needle needs to be carefully pried off in a straight line (use a fork, knife or other instrument to support it in the center).